INCLUSION

Nous rendons l'espace public accessible à tous.

REMPLACEMENT

Neuf, cassé, remplacé, sprayé, repeint, vieux, rafraîchi.

Bollards de protection

Nos bollards de protection

en un coup d'œil

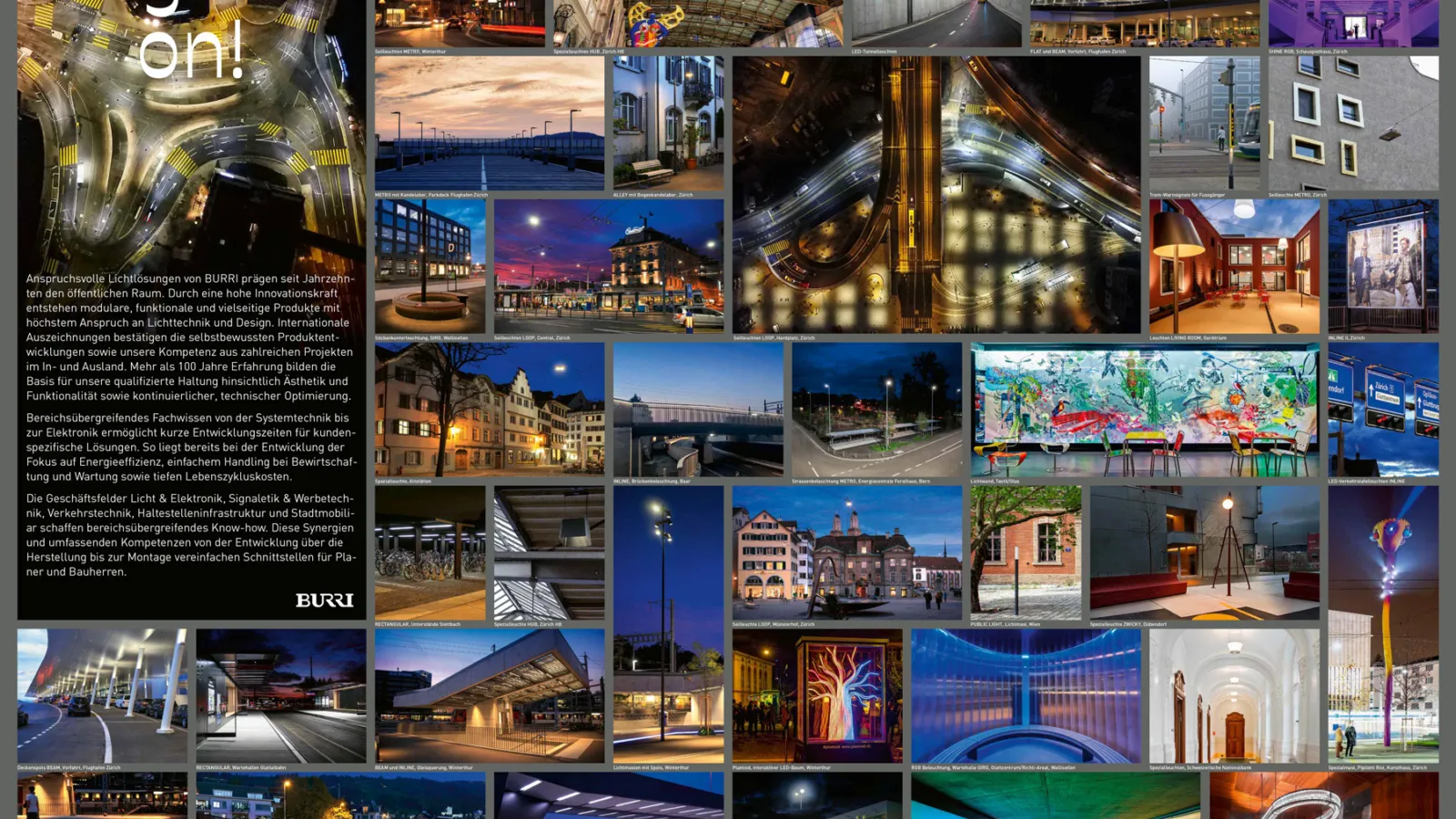

Les bollards BURRI s'adaptent : Aux événements, à leur environnement, à l'architecture et au paysage urbain ainsi qu'aux dernières avancées techniques. Des détails astucieux garantissent une grande aptitude à l'usage quotidien ainsi que des coûts de cycle de vie réduits.

Télécharger l'affiche